-

Is a self bunded diesel fuel storage tank resistant to UV radiationJan 04, 26Self-bunded diesel fuel storage tanks are generally designed to exhibit a certain level of UV radiation resistance, a key feature to ensure long-term structural integrity and performance when exposed to outdoor environmental conditions...

-

How to ensure the environmental protection of self bunded diesel fuel storage tank maintenanceJan 04, 26Ensuring environmental protection during the maintenance of self-bunded diesel fuel storage tanks requires a systematic approach that covers pre-maintenance preparation, in-process control, and post-maintenance management...

-

How to detect leakage in a self bunded diesel fuel storage tankJan 04, 26Detecting leakage in a self-bunded diesel fuel storage tank relies on a combination of integrated monitoring systems and regular manual inspections, ensuring timely identification of even minor leaks to prevent environmental contamination and safety hazards. ..

-

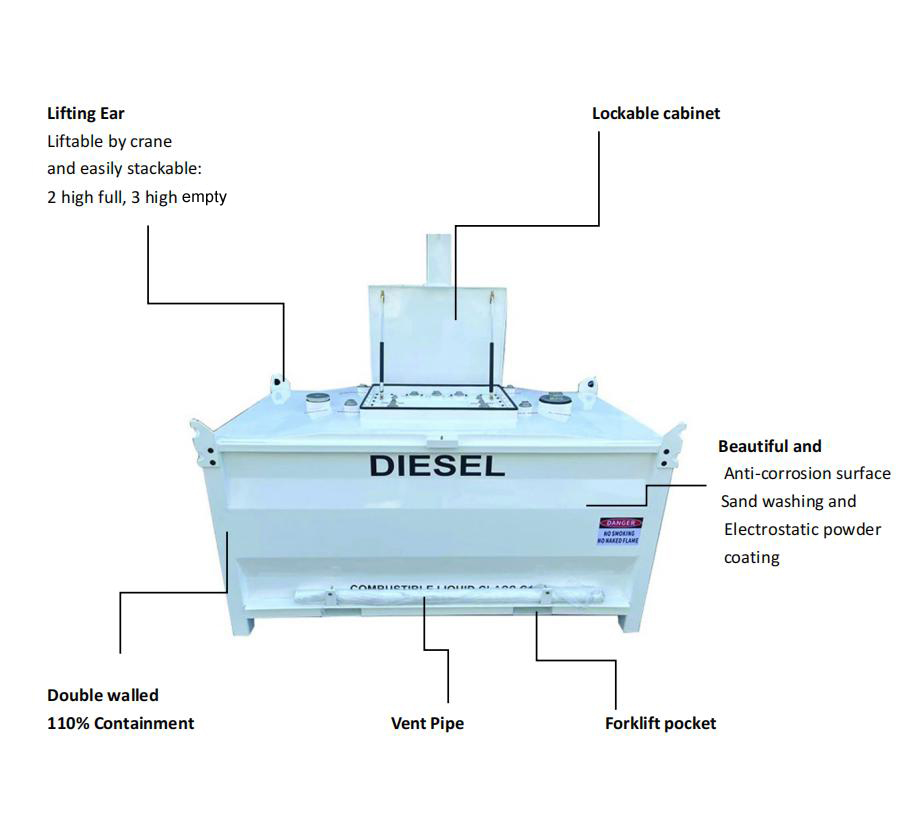

What safety features does a self bunded diesel fuel storage tank haveJan 04, 26Self-bunded diesel fuel storage tanks are designed with multiple integrated safety features to minimize risks associated with fuel storage, including leaks, fires, and environmental hazards...

-

How to install a self bunded diesel fuel storage tank correctlyJan 04, 26Installing a self bunded diesel fuel storage tank correctly is crucial for ensuring operational safety and long-term reliability. Before starting the installation process, thorough preparation is essential...

-

What is the working principle of portable diesel fuel storage tanksDec 31, 25Portable diesel fuel storage tanks operate based on the core principles of sealed containment, controlled fluid transfer and safety protection, integrating mobility with reliable fuel management...

-

Do portable diesel fuel storage tanks have leakage protectionDec 31, 25Portable diesel fuel storage tanks are widely used in various fields due to their mobility, and leakage protection is one of their core safety performance indicators...

-

What safety measures are needed for portable diesel fuel storage tanksDec 31, 25Implementing comprehensive safety measures is essential to mitigate risks associated with portable diesel fuel storage tanks, as diesel is a flammable and potentially hazardous substance...

-

Can portable diesel fuel storage tanks be moved easilyDec 31, 25The ease of moving portable diesel fuel storage tanks depends on multiple factors, including material selection, structural design and auxiliary features...

-

Which material is suitable for portable diesel fuel storage tanksDec 31, 25Choosing the right material for portable diesel fuel storage tanks is crucial to ensure safety, durability and compatibility with diesel fuel. ..